I wanted to have a decent set of bucket seats for the driver and passenger. One of the biggest reason is you may want aftermarket seats is you can have 5 point seatbelts the will install through the seat. Meaning the belts are in the best position to protect the occupant. Anther great reason for seats is they will hold you in place far better, making driving more predictable. In order to install the shoulder portion of the belts my thought was to add a bar just behind the seats and run it to the floor. But the floor is not very well supported and flimsy sheet metal. So floor plates will be installed and run bracing from the floor plate to the uni-rail plate that was installed earlier and can be found here

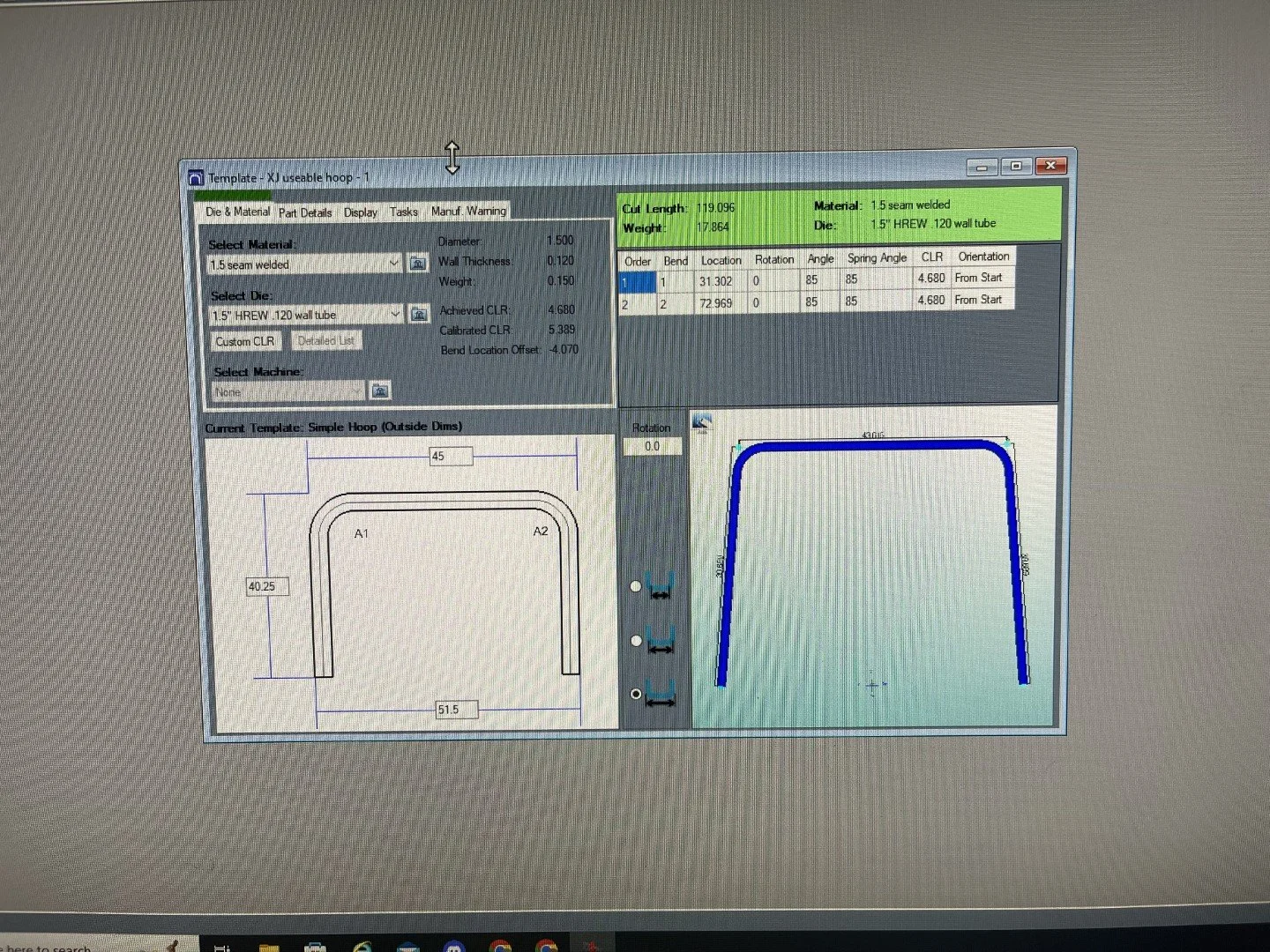

I started with taking some measurements. plugged them into bend-tech software to aid in sorting out angles and lengths. Went to the garage and bent some tube. When I went to fit it in the Jeep the fitment was ok and it would work so I welded it in. But there was an Issue. A pretty big one, I didn’t measure with the seats installed and it was just not going to work at all, so the whole thing had to come out and start over.

Wile this was a frustrating and costly mistake. This is what fabricating is and sometimes errors happen.

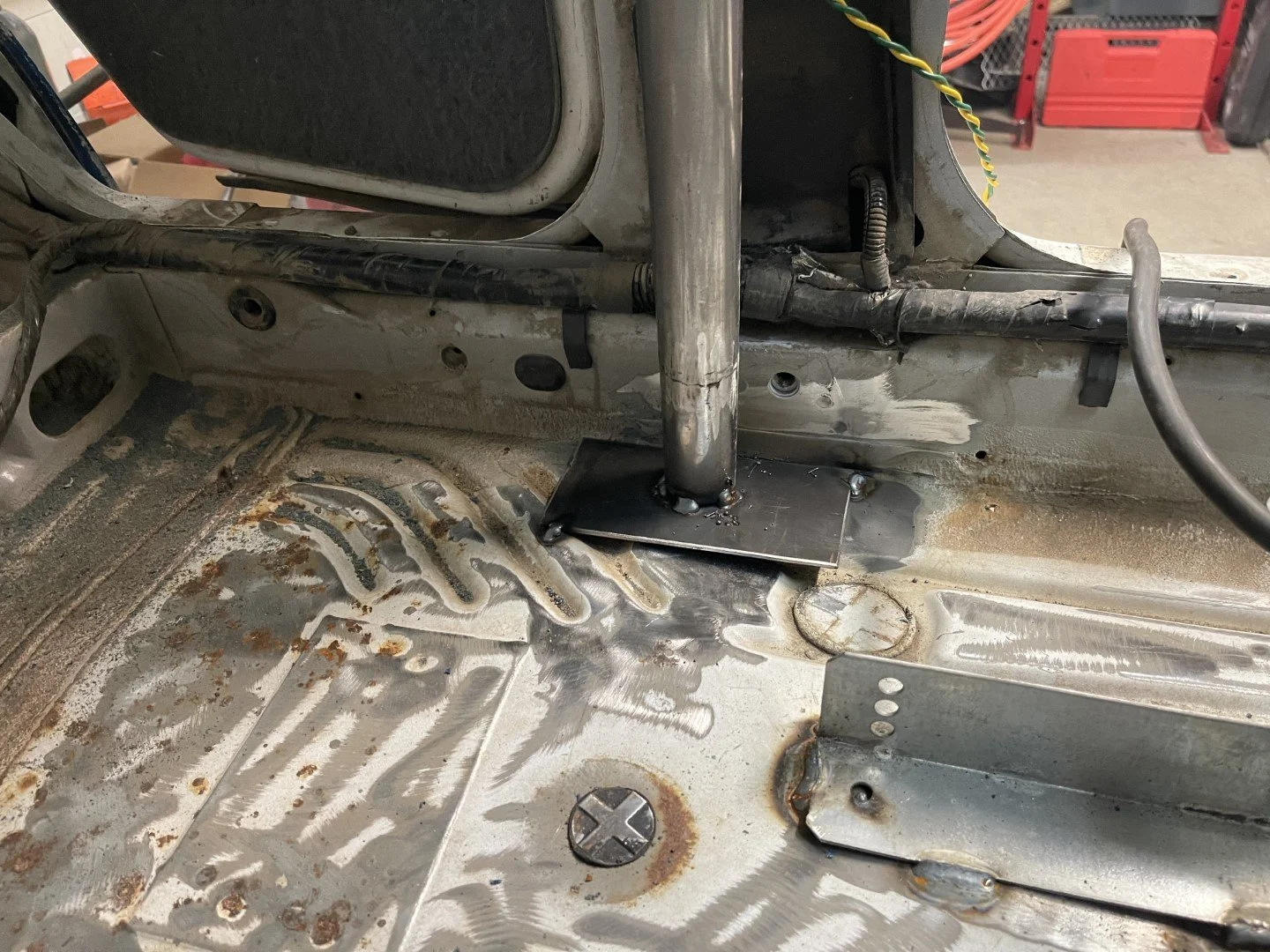

So after re-doing everything we already did. I now have a slightly wider tube that overall fits better and will be situated further back to accommodate the seats. I left the old floor plates figuring I would do nothing but mangle the floorboard attempting to remove it. I had to install new floor plate just behind the first ones.

New tube fits much better and we will add a couple tubes going almost to the front of the seats to triangulate that rear bar so it wont just fold over in the event of a roll over.

On the next post we will look at floor plates and how we are goin to tie into the uni rail