Putting a roll bar or a cage in a uni-body vehicle is challenging. Having welded in all that plate on the uni-rail will come in handy because I will have something with substance to tie the cage too. Floor plates are an ok option here. The idea is to spread the load out over a larger area. I would suspect some would stop there.

I drilled holes in the corners of all the floor plates to allow some bolts to go through and attach the the floor plate on the under side of the body effectively sandwiching the floor pan between the two plates. The floor pan just doesn’t have a lot of structure to it. I did two different types of gusseting mostly because one set was much closer than the other set to the uni-rail.

Started with some cardboard and cut it down to the shape I wanted then cut the shape out of steel then welded it in. In the back I went with a tube. It was further away that the first floor plate so the tube made it a little easy to reach. I used the corner out of the first hoop I bent that was wrong. Additionally I used the down legs from that hoop to make the tubes that go from the roll bar to the front of the drivers seat. So I ended up reusing much of the mistake from the first hoop.

The front floor plate for the passenger side was a little tougher. The floor and well almost everything on this side has been bashed in a little from prior rocks so we weren’t even close to square. I just added a few peices of scrap to help gusset that in place.

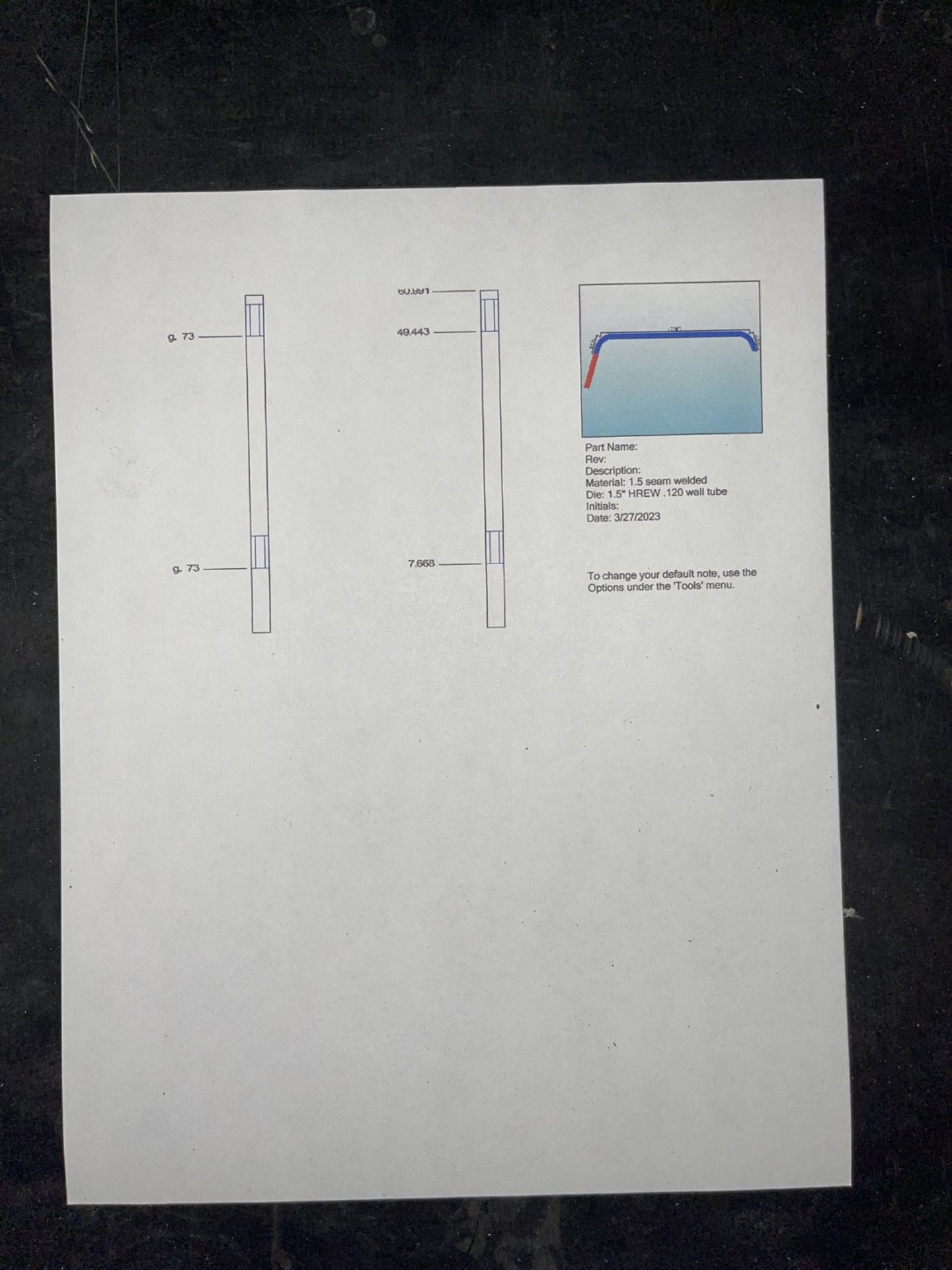

Now we will get started on the belt bar. I take some measurement’s and plug them into bend tech and it spits out some bend locations and angles for me.

Here are a few shots of the bending work. One day I will do a blog or maybe even make a video about bending.

Lastly we fitted and welded the belt bar in.

I’m fairly happy with how it came out. Sure, there are a few things that could be better.

The bars could have much tighter margins and be closer to the body, I would like to find or develop better ways of joining the roll bar into the uni rail. All things considered, I haven’t done tube work in years and never really did a ton of it when I did. I think it will be plenty strong for a low-speed low, energy roll. However, this is in no way to be considered a cage. It’s a roll bar at best. It should offer more protection than just the body itself and gave a good place to mount shoulder belts.

Next, we will start painting the interior with a bed liner product. So my guess is lots of masking!